Industrial Grade 3D Printers

The FORTUS 400mc is the second largest of the Maker Lab’s 3D printers. It holds up to two 92 cubic inch canisters of both support and part material. The 400mc is capable of using a multitude of different plastics and is instrumental in producing parts for senior design projects and many ongoing research projects. The 250mc is smaller, only uses a single type of material, and operates at temperatures lower than those of the 400mc. The 250mc holds approximately a quarter of the total material that the 400 holds. However, what the 250mc lacks in versatility, it makes up for in speed. Both FORTUS printers are capable of soluble support material for complex parts.

The GEARBOX HT2 is the latest addition to the Maker Lab. It is one of the first open source high temperature filament printers on the market that offers support material and a large build area. Since it is open source, we can accommodate specialized slicing requests. It is planned to primarily use the system for cheaper, stronger parts in ULTEM 1010.

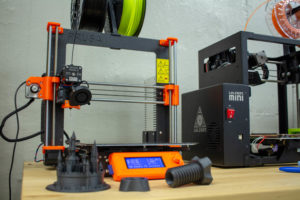

Consumer Grade 3D Printers

The Cube Printer Farm will be a set of 14 3D Systems Cube 3 printers converted to RepRap (open source). This will allow for mass printing small objects or breaking up a large object into many parts to drastically reduce print time. These printers will run basic PLA and will be hooked into one server. It is anticipated this project will be completed later this year.

The Cube Printer Farm will be a set of 14 3D Systems Cube 3 printers converted to RepRap (open source). This will allow for mass printing small objects or breaking up a large object into many parts to drastically reduce print time. These printers will run basic PLA and will be hooked into one server. It is anticipated this project will be completed later this year.

The Formlabs Form 3B is a Stereolithographic (SLA) 3D printer that utilizes Digital Laser Projection (DLP) to cure UV sensitive resin. The printer is capable of resolution ranging from 25-100 microns and has a maximum build size of 14.5cm x 14.5cm x 18.5cm. We also house washing and curing chambers for post-processing. We can polish clear parts upon request. Flexible resin is available, and is the most flexible material we can process in the Maker Lab. High temperature resin is available for applications ranging up to 240C.

The Formlabs Form 3B is a Stereolithographic (SLA) 3D printer that utilizes Digital Laser Projection (DLP) to cure UV sensitive resin. The printer is capable of resolution ranging from 25-100 microns and has a maximum build size of 14.5cm x 14.5cm x 18.5cm. We also house washing and curing chambers for post-processing. We can polish clear parts upon request. Flexible resin is available, and is the most flexible material we can process in the Maker Lab. High temperature resin is available for applications ranging up to 240C.

3D Scanning

Machining

The HAAS TL1 Lathe is a CNC lathe with a 12-horsepower drive and is capable of spindle speeds up to 2000 rpm. The lathe can be operated either manually or from a CNC controller. The lathe can feed at rates up to 450 inches per minute in both the x- and z-axes. It is excellent for general turning purposes.

The HAAS TL1 Lathe is a CNC lathe with a 12-horsepower drive and is capable of spindle speeds up to 2000 rpm. The lathe can be operated either manually or from a CNC controller. The lathe can feed at rates up to 450 inches per minute in both the x- and z-axes. It is excellent for general turning purposes.

The Maker Lab has a HAAS OM2 CNC machine used for small scale machining. The 5-horsepower drive can produce spindle speed of up to 30,000 rpm and feed rates of up to 757 inches per minute in the x-, y-, and z-axes. The small machining volume and rapid speeds make this machine ideal for small, precise prototype parts. It is retrofitted with air filtration to enable graphite and other hazardous material milling.

The Maker Lab has a HAAS OM2 CNC machine used for small scale machining. The 5-horsepower drive can produce spindle speed of up to 30,000 rpm and feed rates of up to 757 inches per minute in the x-, y-, and z-axes. The small machining volume and rapid speeds make this machine ideal for small, precise prototype parts. It is retrofitted with air filtration to enable graphite and other hazardous material milling.

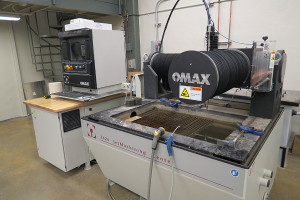

The OMAX 2626 JetMachining Center is an abrasive water-jet cutter capable of producing water pressures up to 50,000 psi. The water-jet cutter is useful for cutting sheet materials that are up to a thicknesses of more than an inch. Materials that can be cut include plexiglass, acrylic, aluminum, and some kinds of steel. Using the proprietary OMAX software, long and complex series of cuts can be made with exceptional precision.

The OMAX 2626 JetMachining Center is an abrasive water-jet cutter capable of producing water pressures up to 50,000 psi. The water-jet cutter is useful for cutting sheet materials that are up to a thicknesses of more than an inch. Materials that can be cut include plexiglass, acrylic, aluminum, and some kinds of steel. Using the proprietary OMAX software, long and complex series of cuts can be made with exceptional precision.